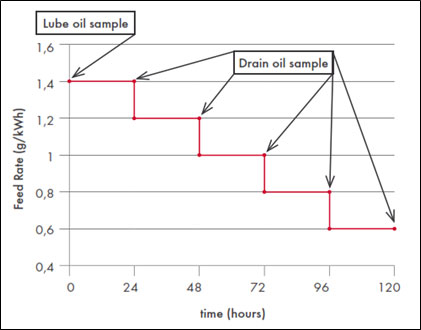

Five factors determine the lubricating oil feed rate:

Both engines with mechanical lubricators and automatic lubricators can optimize the consumption of Cylinder Oil. Certainly, the optimization is more efficiently applied to Engines with automatic lubricators (Alpha Lubricators, Pulse etc.)

Our program assists our clients successfully to mimimize the Cylinder Oil cost while protecting the engine from abrasive or corrosive wear.

Further to regular CSA, we are offering our clients the possibility to perform, Sweep Test a tool proposed by MAN and Quick Test/Engine Screening, tools proposed by WinGD & Wartsila.

Further to regular CSA, we are offering our clients the possibility to perform, Sweep Test a tool proposed by MAN and Quick Test/Engine Screening, tools proposed by WinGD & Wartsila.

It must be understood that the drip oil is analysed to evaluate the condition inside the combustion chamber. There is a common misunderstanding that the only parameters that play a role is Iron Content and the residual BN. The reality is that they are the most significant parameters.

| PARAMETERS | METHODS | PURPOSE |

|---|---|---|

| Base Number (BN) | ASTM D 2896 | The base number describes the alkalinity of the oil, which is necessary to neutralize the acidic components formed during combustion to prevent the risk of corrosive wear. |

| Iron (Fe) | ASTM D 5185 | Is, beside the base number, the most important indication for any problem in the liner. It can indicate corrosive or abrasive wear. Corrosive wear is due to acid condensation on the liner wall. Abrasive ware is most probably due to liner or ring wear. |

| Kinematic Viscosity (KV) | ASTM D445 | Changes in Kinematic Viscosity can indicate contamination. |

| Flash Point | ASTM D 3828 | change in the Flash point of the oil shows fuel ingress or contamination. |

| Soot/Insoluble | ASTM E2412/ IP316 | The soot or oil-insoluble level in the oil gives an indication on combustion quality. |

| System Oil Dilution | In-house method | The System oil dilution shows the performance of the stuffing box and helps to make the necessary corrections in the test results for viscosity, BN, Fe and PQ Index. |

| PQ Index | Manufacturer | The PQ Index identifies ferromagnetic particles in the oil. |

| This allows to assess the iron wear level and to categorize it as abrasive or corrosive wear. | ||

| Wear elements: Aluminium (Al), Chromium (Cr), Copper (Cu), , Lead (Pb), Tin (Sn) |

ASTM D 5185 | Wear and contaminant metals are either wear particles in the oil caused by abrasive or corrosive wear on machinery parts or ingress of external contaminants. Elemental spectroscopy analysis by ICP can precisely determine all metals, including wear, contaminant and additive metals from trace level to higher concentrations. For some elements, there are several possible sources. For example, silicon in the oil can be caused by wear (piston crown material), antifoam additives or contamination (dirt or sand). Only by evaluating the complete set of results is it possible to determine the exact sources of the particles. |

| Contaminant elements: Sodium (Na), Silicon (Si), Molybdenum (Mo), Nickel (Ni), Silver (Ag), Vanadium (V) |

ASTM D 5185 |

The drip oil that is collected in the piston underside space, contains not only the Used CLO, but also System Oil that has leaked through the Stuffing Box.

The drip oil that is collected in the piston underside space, contains not only the Used CLO, but also System Oil that has leaked through the Stuffing Box.

This means, that actually, the results of the analysis of the Drip Oil do not reflect the true condition inside the Cylinder and they have to be corrected according to the extent of the System Oil Dilution.

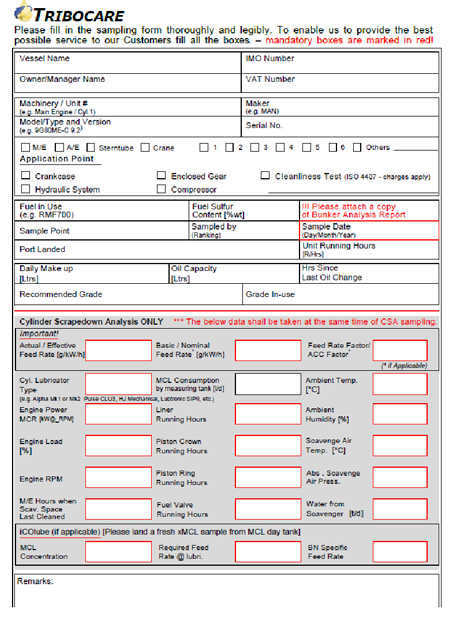

Total evaluation takes place, after obtaining the corrected values and in accordance with the info given in the submission form.

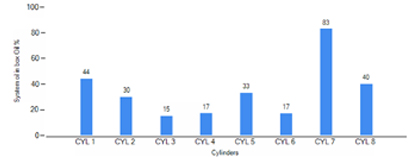

Investigations have shown, that engines of the same design may experience very different piston running behaviours. The factors that influence the

Our technical team will give tailor-made instructions for the optimization of Cylinder Oil feed rates, based on all the above information.

Cylinder Oil Analysis Brochure

Need help or have a question?

UAE +971 65528799

UAE +971 65528799 Singapore + 65 62642840

Singapore + 65 62642840 China +86 18621601008

China +86 18621601008  Germany +49 4102 6075

Germany +49 4102 6075 Greece +30 2130319384

Greece +30 2130319384 Hong Kong +852 5702 7694

Hong Kong +852 5702 7694

UNITED ARAB EMIRATES

Tribocare FZC

A2-74 SAIF Zone

Sharjah, UAE

T: +971 65528799

E: sharjah@tribocare.com

SINGAPORE

Tribocare PTE LTD

32, Pandan Road,

Singapore 609279

T: + 65 62642840

E: singapore@tribocare.com

CHINA

Tribocare Shanghai CO., LTD.

Room 202 Block 32, No.3999

Xiupu Road, Pudong District,

Shanghai, China

地址:上海市浦东新区秀浦路3999弄, 32号二层202室

T: +86 18621601008

E: china@tribocare.com

GERMANY

Tribocare GMBH

E: germany@tribocare.com

GREECE

Pentelis 53

Marousi 15126

Greece

T: +30 213 031 9384

Mob: +30 694 649 0604

E: greece@tribocare.com

NETHERLANDS

Tribocare B.V.

Delta-Industrieweg 14

Stellendam,

Netherlands

3251 LX

E: netherlands@tribocare.com

USA

Tribocare INC

E: americas@tribocare.com

Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur. " Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur.