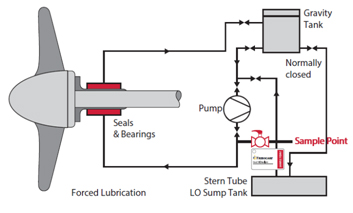

The IACS (International Association of Classification Societies) in UR Z21 states that Stern Tube lubricating oil analysis is to be carried out at regular intervals not exceeding six (6) months, taking into account IACS Rec. 36. The documentation on lubricating oil analysis is to be available on board.

Oil samples, to be submitted for the analysis, should be taken under service conditions.

According to Rec. 36

Each analysis, to be performed by an appropriate method, should include the minimum parameters as listed:

In Tribocare we are one of the few labs that have the capability of measuring Chlorides, along of course all the other required parameters.

Of course the majority of Ship Owners and Operators monitor the oil condition of Stern Tube, even in shorter intervals of 3 or 4 months.

| Test Parameter | Method |

|---|---|

| Kinematic Viscosity @40°C | ASTM D 445 |

| Water | ASTM D 6304 |

| Acid Number | ASTM D 664 |

| Soot / Insolubles | (ASTM D789913;ASTM D89314; ASTM E241210) |

| Oxidation | (ASTM E241210) |

| Chloride | XRF/ICP |

| PQ Index | Maker |

| Chromium, Copper | ASTMD 5185 |

| Iron, Lead | |

| Tin, Antimony | |

| Nickel, Calcium | |

| Sodium, Silicon | |

| Zinc,Phosphorous |

Esterification reaction with an alcohol and organic/inorganic acid produces synthetic ester oil. Ester oil is also available by naturally produced triglycerides from vegetable or animal source.

Esters derived from vegetable resources with double carbon-hydrogen bonds are referred as unsaturated esters because the molecule is not fully saturated with hydrogen atoms.

Ester oil can be classified as fully saturated, partly saturated and unsaturated.

Iodine value is a measure of the degree of saturation. Iodine value less than ten shows the ester oil as fully saturated. For partially saturated ester oil the Iodine value is between sixty and eighty. Unsaturated ester oil Iodine value ranges from ninety to hundred.

The reverse reaction of esterification is hydrolysis. By consuming water at high temperatures, esters can break into acids and alcohols. Unsaturated ester oil hydrolytic stability is weak. Carboxylic acid and other acids forming from poor hydrolytic stability of ester oil can cause damage to machinery and seals.

The typical factors which can accelerate the hydrolysis reaction is as follows: Chemistry of base oil, amount of water in the oil, higher temperature of the oil, products formed in the oil from the reaction which can further accelerate the action, emulsifiers included in the oil formulation.

The typical factors which can accelerate the hydrolysis reaction is as follows: Chemistry of base oil, amount of water in the oil, higher temperature of the oil, products formed in the oil from the reaction which can further accelerate the action, emulsifiers included in the oil formulation.

Basic and acidic components also cause hydrolysis reaction. Hence ester oil should not mix-up with other oil grades, additives present in those oils can have a detrimental effect on ester oil.

Fully saturated synthetic ester oil is stable and is having better oxidation resistance whereas unsaturated ester oil can be easily oxidized. Oxidation can cause increase in viscosity, elevated acid number and sludge formation.

For the in-use EAL oil quality, prime importance should be given on Acid number, viscosity, sludge and water content test parameters.

Iodine value can be tested on fresh oil batches to ensure the type of ester oil.

During the transition from mineral lube to EAL it should be ensured that there is no residue of previously used mineral type lube by repeatedly flushing the system by the EAL grade. Additive elements like Calcium, Zinc can be considered as indicators of mineral type oil presence in the used EALs provided the previous lube oil in the system comprise these additives.

After the introduction of EAL in the system if shoot up of Lead is noted on the used oil sample it should be identified as oil soluble or non-soluble Lead by lab testing. If it is soluble and stabilizing after certain service period, leaching could be the cause of increased Lead and it is not an alarming situation and not likely to cause secondary wear.

In the transition decision another important factor to be considered is to install the EAL compatible seals. Usage of mineral lube compatible seals with EALs can lead into catastrophic failures.

Water content in the in-service EAL shall be regularly monitored and preferably maintain less than 0.2 percentage. Higher water content can lead into EALs property change.

After the introduction of EAL in the system if shoot up of Lead is noted on the used oil sample it should be identified as oil soluble or non-soluble Lead by lab testing. If it is soluble and stabilizing after certain service period, leaching could be the cause of increased Lead and it is not an alarming situation and not likely to cause secondary wear.

In the transition decision another important factor to be considered is to install the EAL compatible seals. Usage of mineral lube compatible seals with EALs can lead into catastrophic failures.

Water content in the in-service EAL shall be regularly monitored and preferably maintain less than 0.2 percentage. Higher water content can lead into EALs property change.

Need help or have a question?

UAE +971 65528799

UAE +971 65528799 Singapore + 65 62642840

Singapore + 65 62642840 China +86 18621601008

China +86 18621601008  Germany +49 4102 6075

Germany +49 4102 6075 Greece +30 2130319384

Greece +30 2130319384 Hong Kong +852 5702 7694

Hong Kong +852 5702 7694

UNITED ARAB EMIRATES

Tribocare FZC

A2-74 SAIF Zone

Sharjah, UAE

T: +971 65528799

E: sharjah@tribocare.com

SINGAPORE

Tribocare PTE LTD

32, Pandan Road,

Singapore 609279

T: + 65 62642840

E: singapore@tribocare.com

CHINA

Tribocare Shanghai CO., LTD.

Room 202 Block 32, No.3999

Xiupu Road, Pudong District,

Shanghai, China

地址:上海市浦东新区秀浦路3999弄, 32号二层202室

T: +86 18621601008

E: china@tribocare.com

GERMANY

Tribocare GMBH

E: germany@tribocare.com

GREECE

Pentelis 53

Marousi 15126

Greece

T: +30 213 031 9384

Mob: +30 694 649 0604

E: greece@tribocare.com

NETHERLANDS

Tribocare B.V.

Delta-Industrieweg 14

Stellendam,

Netherlands

3251 LX

E: netherlands@tribocare.com

USA

Tribocare INC

E: americas@tribocare.com

Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur. " Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur.